The following publication has been lightly reedited for spelling, grammar, and style to provide better searchability and an improved reading experience. No substantive changes impacting the data, analysis, or conclusions have been made. A PDF of the originally published version is available here.

On September 16, business and industry leaders from the Great Lakes region met in Rochester, N.Y., to discuss the economic and environmental challenges facing the region. This event marked the first annual meeting of the Council of Great Lakes Industries, a binational organization dedicated to promoting the economic vitality of the region in harmony with the human and natural resources of the Great Lakes. This conference particularly emphasized the environmental challenges facing Great Lakes industries and efforts by industry to arrive at policy solutions that accommodate both economic growth and environmental protection. Speakers discussed the increasing necessity of an active business community role in policy formation in light of increasingly stiff global competition and outlined the approaches which industry can use to become more actively involved in the public policy process. Through efforts such as this council and greater participation by business in the policy process, public policy can be crafted that is consensus based, and consequently less costly and more effective.

This Chicago Fed Letter reviews the proposals of several speakers at this conference and provides some examples of the benefits anticipated from greater industry involvement in public policy formation in the Great Lakes region.

Why does industry need to be more involved in the policy process?

The rapid pace of change throughout the world means that businesses are operating under new global pressures that often require firms to be low-cost producers of high quality products and to accomplish this in a clean environment. The costs of operating in such an environment can be staggering. The U.S. already spends more on the environment than any other country with the cost of environmental cleanup estimated to be running at just over 2% of gross national product and rising.1 To put this in perspective, this figure is equal to roughly 40% of U.S. defense expenditures.

In order to succeed under these conditions, industry is looking for ways in which to serve as a full and active participant in setting regional policy. All too often the policy and legislative process has resulted in regulations that are unnecessarily burdensome in relation to the benefits achieved and that impede economic growth. This seems especially so in the environmental arena. Good environmental policy should identify which environmental risks matter most and should direct resources toward reducing these risks. Both a cleaner environment and more economic growth can often be achieved through an approach by which the business community sets up an internal goal of zero discharge of hazardous waste and works cooperatively with all environmental stakeholders to fashion sound public policy. For example, companies such as Monsanto, DuPont, AT&T, and 3M are pursuing strategies designed to cut emissions and waste discharge. 3M’s goal is to reduce air and water emissions by 90% and solid waste by 50% by 1995 from 1990 levels, while cutting the inflation-adjusted cost per unit of most products by 10%.2 At stake is the ability to balance economic growth with environmental interests and to move away from the traditional regulatory environment where command and control strategies are imposed on business operations at unacceptably high costs.

The potential for reconciling the apparently competing interests of economic growth and environmental quality is best exemplified in the Council of Great Lakes Industries’ efforts to create a Total Quality Environmental Management Award for Great Lakes industries. Patterned after the Malcolm Baldrige National Quality Award (which recognizes firms that integrate total quality into their management principles and practices), the council’s award is designed to recognize companies that show a commitment to environmental management. Just as the Baldrige award provides a benchmark for improvement even for those firms that never compete for the award, the Total Quality Environmental Management Award will be used to raise industry standards in general and to show how firms can balance economic success and sound environmental practices. The award winners will provide models, which other firms could adapt. Toward this end, the council has developed a self-assessment matrix that will identify progress among award applicants and help educate companies outside of the award process about the concepts, benchmarks, and methods behind quality environmental management. Now that the Council of Great Lakes Industries has completed the development of the award, the award’s sponsorship rests with the Council of Great Lakes Governors.3

Environmental issues—an example of industry’s participation in public policy

The potential for cooperation and consensus building through industry leadership was reflected in the remarks of Denis Wilcock, president of Dow Chemical Canada, Inc. As exemplified by a pioneering effort in Canada, an industry leadership approach can solve environmental problems by building a consensus among key stakeholders (residents, local businesses, and local leaders) in the community. This approach recognizes that it has become imperative for the chemical industry to take stewardship for all stages of a product, ranging from development to disposal. But fulfilling the responsibilities of that stewardship at socially acceptable costs also requires public involvement and agreement on the processes of production and disposal. Involving the public in the decision-making process is expensive at first. However, the benefits can be higher still because community acceptance can be achieved. For example, Wilcock noted that a recent Dow Chemical plant expansion proceeded without public objection after the company had solicited the input of community leaders and residents. Given that the public’s perception of the chemical industry is often one of suspicion, community outreach can reduce fears that often lead to costly delays.

This process has been formalized through a group called “New Directions,” which is a cooperative effort between environmentalists and business to establish environmental goals for Canada. This multi-stakeholder group has established an agenda emphasizing sustainable development, pollution prevention, and an action plan that establishes a priority list of toxic pollutants along with a process for reducing or eliminating them. During the initial phase of negotiations, the group does not include government representatives so that a consensus among environmental and business interests can be reached without participants having to work at the details of implementation or becoming involved in political lobbying. Once a consensus has been reached, the results can then be presented to the relevant government organization.

While no such formal group currently operates on the U.S. side of the border, one illustration of the potential benefits of cooperative industry approaches concerns the implementation of certain aspects of the Clean Air Act by the electric power industry. The Clean Air Act Amendments of 1990 is a comprehensive piece of legislation presented in 11 titles that will impose significant and direct costs onto utilities and industrial sources.4 Vincent Tobin, vice president with the New York Power Authority, noted that compliance with the act forces the full social costs to be directly paid as a primary expense by utilities. In particular, Title IV dealing with acid rain and Title I dealing with ambient air quality (including ozone) will require some electric power companies to purchase the rights to pollute as a condition for continued and expanded operations. The costs of purchasing pollution rights may be especially high in nonattainment areas. To obtain a new source permit in nonattainment areas, a company may be required to reduce overall emissions of that pollutant in the affected locale by as much as 150%. These features of the Clean Air Act amendments impose a great challenge to utilities to meet consumer demands for both clean air and low-cost, readily available electric power.

One method for improving air quality while containing customer price through industry and consumer cooperation is demand side management (DSM). DSM encourages customers to conserve energy so as to forestall costly additions to electric generating capacity. Energy saved through DSM will reduce power plant emissions and economize on the purchase of either allowances or offsets. DSM has been implemented in the New York Power Authority’s service area through a variety of power-saving ideas and services which have been provided by the utility to its customers. By forming a partnership between utilities and customers, the goals of cleaner air, energy efficiency, and cost containment can be reached.

In contrast to the successful beginnings of industry-stakeholder partnerships in Canada and in the New York Power Authority’s service area, Superfund and other legislation, which mandate hazardous waste cleanup of polluted sites, exemplify the onerous costs to industry and society of stringent regulation designed without significant industry input or consensus. Susan Sadler, a partner with the Detroit law firm of Clark, Klein, and Beaumont, indicated that environmental litigation based on site cleanup liability has mushroomed at both the federal and state levels. Superfund and related state legislation have vastly expanded the liability for toxic waste cleanup in many instances to include such parties as previous owners, banks, and other lending institutions. The economic effect has been to make companies wary of expansions and relocations at sites where chemicals may have once been disposed (often older developed areas such as many central cities), in order to prevent incurring liability for the cleanup. At the same time businesses are encouraged to place new development in “greenfields” where they can be reasonably certain that toxic chemicals will not be found in the soil.

Profile: Council of Great Lakes Industries

Mission: uniting major Canadian and U.S. firms and associations with interests and investments in the Great Lakes basin to promote the economic vitality of the region, in harmony with its human and natural systems.

Strategic goals

- Enhance the economic vitality of the region.

- Advocate the common interests of industry.

- Expand public awareness of industry’s contributions.

- Support environmental progress.

- Create a forum to assist in industry growth and development.

Programs include work groups, community awareness programs, public outreach strategies, sabbaticals or personnel exchanges, and technical training designed to develop productive interfaces between industry and other basin stakeholders such as government, colleges, universities, and trade associations.

Furthermore, the process by which Superfund cleanup sites are determined and resolved often entail staggering costs. Even within the designated Superfund sites, there are wide-ranging and uncertain risks from the site’s contamination. The lack of communication between industry and the public has led to perhaps erroneous public perception that anything short of complete removal of the soil in the affected site is inadequate. But such a policy may result in massive cleanup efforts when a more limited cleanup would result in greater overall health and esthetic benefits per dollar expended. With the federal Superfund program facing reauthorization in 1994, industry has an opportunity to help revise cleanup procedures to ensure that the costs of Superfund cleanups bring about greater public benefits. Since nearly 36% of the federal Superfund sites are located within the Great Lakes region, the involvement of the Council of Great Lakes Industries in defining a more rational approach to these cleanup efforts would greatly benefit the region’s residents.

As an example of how a government agency can benefit from a multiple stakeholder policy process, Gordon Durnil, the U.S. commissioner to the binational International Joint Commission (IJC) spoke on the topic of eliminating toxic substance discharge into U.S.-Canada boundary waters. The IJC is a nonpartisan commission that is charged with protecting the ecosystem of the Great Lakes and, as part of that charge, has continued to pursue the elimination of toxic discharges into the lakes. In pursuing this goal, the commission solicits scientific information from all of the constituencies in the Great Lakes basin. Through such a process the commission has recently established a list of the most onerous toxic substances which need to be eliminated.

Similar to the spirit of the Council of Great Lakes Industries, the IJC has chosen to adopt a balanced approach to reaching the twin goals of eliminating these toxins from the Great Lakes while protecting the economic vitality of the region. By phasing in regulation, rather than requiring overnight adherence, a realistic timetable can be established to ensure that the most onerous toxic substances will be eliminated while limiting economic dislocation and excessive compliance costs. This approach allows companies to adapt new technologies to meet environmental standards.

What does the future hold for the Council of Great Lakes Industries?

In its first year, the Council of Great Lakes Industries has already begun to demonstrate the potential for greater industry involvement in the environmental field. While continuing these environmental efforts in the coming years, the council’s attention will expand to include economic challenges faced by the region’s industries. This can include such issues as improving advanced and basic infrastructure, education and training of the workforce, and issues of energy cost and availability. An example of government participation in this new style of policy formation in other issues can be found in the forthcoming Canadian National Competitiveness Plan as described by John Capan from the Canadian Ministry of Science, Industry, and Technology. Borrowing from industry’s concept of “total quality management,” the Canadian government has embraced total quality commitment in which innovation and improvement is essential to success in an economy characterized by relatively high costs and high wages. In this innovation-driven model of the economy, competitiveness challenges can be solved only by a consensus. In particular, industry can identify barriers to competitiveness and, by working with local stakeholders, develop strategies for overcoming these barriers and promoting growth.

As the efforts in the environmental area have shown, industry participation as both a leader and a partner can help in crafting economic policy that will promote an economically vital Great Lakes region on both sides of the border. The Council of Great Lakes Industries may serve as a model for others looking for industry leadership and commitment to the public policymaking process.

Tracking Midwest manufacturing activity

Manufacturing output index (1987=100)

| August | Month ago | Year ago | |

|---|---|---|---|

| MMI | 110.7 | 110.8 | 109.4 |

| USMI | 109.6 | 110.0 | 108.4 |

Motor vehicle production (millions, saar)

| September | Month ago | Year ago | |

|---|---|---|---|

| Autos | 5.6 | 5.4 | 6.0 |

| Light trucks | 3.7 | 3.7 | 3.6 |

Purchasing manager’s association: production index

| September | Month ago | Year ago | |

|---|---|---|---|

| MW | 61.1 | 60.0 | 57.9 |

| U.S. | 52.6 | 56.4 | 60.7 |

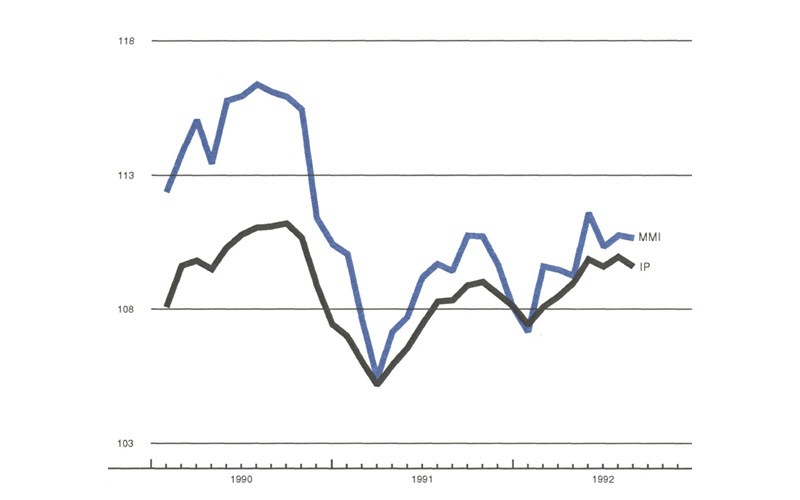

Manufacturing output index, 1987=100

Sources: The Midwest Manufacturing Index (MMI) is a composite index of 17 industries based on month hours worked and kilowatt hours. IP represents the FRBB industrial production index for the U.S. manufacturing sector. Autos and light trucks are measured in annualized physical units, using seasonal adjustments developed by the Federal Reserve Board. The PMA survey for the U.S. is the production components of the NPMA survey and for the Midwest is a weighted average of the production components of the Chicago, Detroit, and Milwaukee PMA survey, with assistance from Bishop Associates and Comerica.

Manufacturing activity in the Midwest edged down slightly (0.1%) in August, on a seasonally adjusted basis, reflecting the recent weakening in auto production and a slowing in Purchasing Managers’ Surveys around the District. While the nation also showed an August decline (down 0.3%), the Midwest continued to fare somewhat better than the nation.

Manufacturing activity over the next few months should improve. Auto production was up in September and both light trucks and autos are scheduled to increase production in the fourth quarter. The Purchasing Managers’ Surveys for production in the District are already showing an improvement in September, despite a steady deterioration at the national level in recent months.

Notes

1 The Economist, “Environmentalism runs riot,” August 8, 1992, pp. 11-12.

2 Business Week, “The next trick for business: taking a cue from nature,” May 11, ]992, pp. 74-75.

3 The Council of Great Lakes Governors, a private nonprofit organization, fosters cooperation on environmental and economic policy issues common to its eight member states: Illinois, Indiana, Michigan, Minnesota, New York, Ohio, Pennsylvania, and Wisconsin and the Canadian provinces of Ontario and Quebec. The council develops regional agreements that are signed and implemented by the Great Lakes governors.

4 For a discussion of the costs of the Clean Air Act on the Great Lakes region, see “The 1990 Clean Air Act: a tougher regulatory challenge facing Midwest industry,” by Donald A. Hanson, Economic Perspectives, Federal Reserve Bank of Chicago , May/June 1992, pp. 2-18.