Manufacturing exit tough on Midwest central cities

If current trends continue, manufacturing activity will soon become extinct as a part of central city economies. The reasons for this exodus are largely the result of shifts in the technology of many types of production activity. Central cities—especially in the Midwest and Northeast—are generally densely populated and somewhat congested. Such conditions are not ideal for production activity. Many central cities vigorously attempt public policies to preserve manufacturing jobs, but the opposing forces appear to be very strong.

At one time, many central cities were the preferred locale for manufacturers. The reasons can be boiled down to two, transportation of laborers and transportation of materials.

As for labor, factories were once teeming with laborers. But due to labor-saving productivity gains, today’s factories are sparsely populated even though they produce many times more output. Senior Business Economist Bill Strauss calculates that today it takes 200 U.S. manufacturing workers to produce the same amount of product as 1,000 workers in 1950. Accordingly, during those earlier labor-intensive times, the transportation of manufacturing workers to the job site figured much more heavily into the factory cost equation. Transportation efficiency once was served by factory neighborhoods in central cities where workers could more easily commute by walking, driving, or by public transportation. The higher living density of central cities also meant that public services such as education and sanitation could be delivered cheaply to workers. Of course, it is not only manufacturing technology that changed. Better highways and rising standards of living (translated into higher car ownership) have also contributed to the ability of factories to staff their factories with (fewer) workers who live farther away. In turn, this opens up factory sites in suburban and rural areas.

Better highways, road vehicles, and logistics technology have also made the transportation of production material to central cities less attractive in comparison to areas of lower population density. Economically, railroads once dominated long-haul truck transportation of materials and components used in manufacturing, as well as the shipment of finished goods to other final markets. The technology of rail favors convergence into a central location (i.e., central cities) rather than the dispersed locations that are served by the crisscross pattern of our now ubiquitous highways. Over time, construction of divided highways and the advent of trucks having features such as refrigeration, trailers, and easily transferred containers have facilitated factory sites served by roads rather than by rail. Accordingly, factory sites can now better take advantage of the low land costs of rural and suburban areas rather than being restricted to those of the central cities.

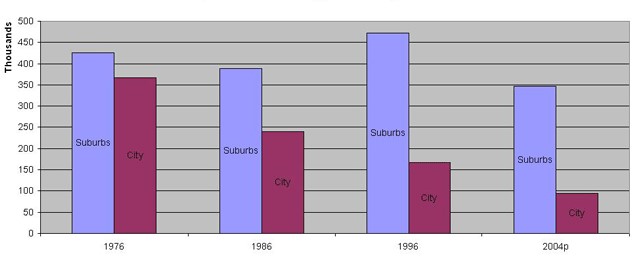

The City of Chicago exemplifies the central city experience with manufacturing jobs. The chart below shows that, by one reckoning, manufacturing jobs in the city have declined from 367,000 in 1976 to under 100,000 today—a loss of approximately 10,000 per year. In contrast, the employment experience of Chicago’s suburban areas has been much milder.

Figure 1. Payroll manufacturing jobs, Chicago SMSA

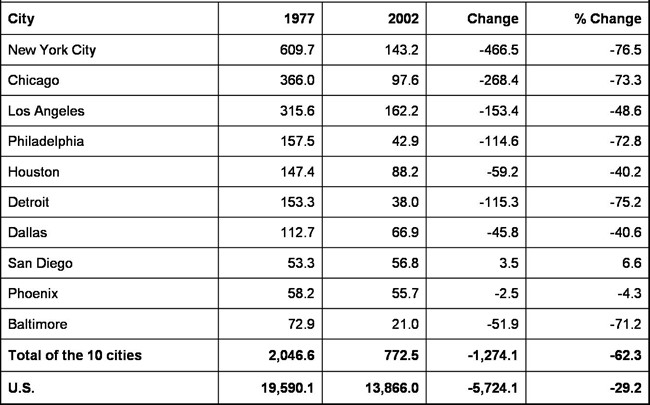

The experiences of other central cities has been somewhat similar to Chicago’s, even some of those cities located in the faster-growing Sunbelt regions. The table below, drawing on data from the Census of Manufactures, describes the manufacturing job changes from 1977–2002 of the 10 most populous U.S. cities (as of 1980). Over the period, manufacturing jobs in these 10 cities dropped by 62%, which is more than double the pace of manufacturing job loss in the overall U.S. Although the job gains of San Diego and the slight loss by Phoenix seem to be exceptions, they are not. Rather, their experience reflects the fact that the land area of those cities has expanded by 2.5 times and 4 times, respectively, through annexation since 1980. At the same time, Midwest city boundaries have remained essentially fixed.

Table 1. Central city manufacturing jobs (in thousands)

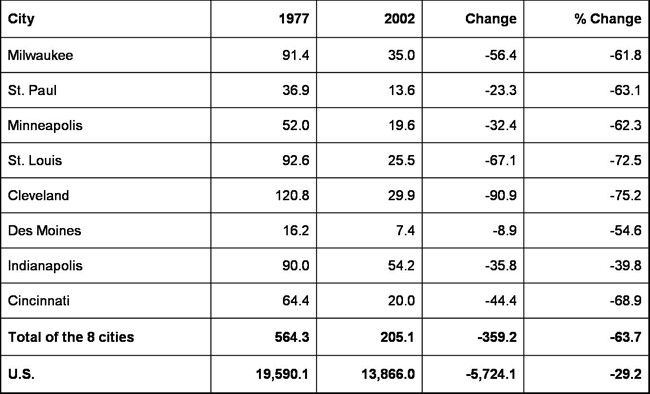

So too, as shown by the table below, the city of Chicago’s experiences are mirrored closely by the central cities of the industrial Midwest. The high population density of places such as central city Milwaukee and Cleveland came about during a different era than the more recent growth of low-density (and expanding) cities of the West and Southwest.

Table 2. Midwest central city manufacturing jobs (in thousands)

Many central cities of the Midwest owe their original existence to manufacturing, so the steep loss of manufacturing jobs in central cities has typically been painful. In response, these cities often attempt to combat manufacturing decline through public policies. For example, some policy initiatives to make manufacturing activity more competitive in cities include clearing land, cleaning up environmental hazards, preserving or setting aside land exclusively for manufacturing purposes, or easing freight transportation congestion. However, so far, the allure of suburban and ex-urban manufacturing locales has been too strong to overcome.