The following publication has been lightly reedited for spelling, grammar, and style to provide better searchability and an improved reading experience. No substantive changes impacting the data, analysis, or conclusions have been made. A PDF of the originally published version is available here.

Manufacturing is currently undergoing a transition from a mass production system to a lean production system, which emphasizes quality and speedy response to market conditions while utilizing technologically advanced equipment and a different organization of the production process. The new manufacturing system has achieved remarkable productivity advances. The success or failure of the Midwest’s manufacturing sector in climbing on board this revolution will be central to the region’s future prosperity due to the historic role of manufacturing in shaping the region’s economy. Successful adaptation to the lean manufacturing system is likely to require significant changes in both the management of factories and the structure of the economy, for example, changes in worker training, job performance, public infrastructure, and perhaps the location of factories and jobs.

The purpose of this Chicago Fed Letter is to outline the differences between the new lean manufacturing system and the prior industry standard, the so-called Fordist system of mass production. Examples from the auto industry are used to illustrate the differences between the two manufacturing systems, as the auto industry in the past has had great influence on the way many other businesses organize their factories.

Henry Ford’s influence on mass production

At the end of the 19th century there were hundreds of small machine shops in Europe and America, each producing no more than 1,000 cars per day.

Automobile manufacturing was revolutionized when Henry Ford introduced the use of interchangeable parts and the moving assembly line to the manufacturing process. The Fordist system of mass production was based on two principles: the Taylorist (after Frederick Taylor) philosophy of separation of intellectual and manual work, and the specialization and separation of work activities into easily learned, repetitive steps. These activities were administered by means of a hierarchical, authoritarian style of management. According to the Fordist system, each worker had one or two tasks, which were repeated over and over. This specialization and repetition of activities give rise to high levels of output at low cost, yet the finished products were often plagued by quality problems. For example, a worker is able to install many wheels and tires per hour by repeating a narrowly defined task. But in doing so, the worker may ignore any visible flaws previously made in the production process. Checking for flaws is the task of someone else—once a quality problem is spotted, an inspector is alerted. Ultimately, the car will be repaired before it leaves the assembly plant, but only after it has gone through the entire assembly line. Typical of Fordist automobile assembly is a large number of vehicles at the end of the assembly line, waiting to be repaired.

The Fordist system is geared to the mass production of a limited number of models and is unable to respond quickly to changes in demand. Fordist manufacturing maximizes output of a particular product by running machines with as few interruptions as possible, requiring relatively large buffer stocks of inventories set up at the various steps of production. In case a quality problem occurs, for example at a piston machining operation, a large buffer stock provides enough correctly machined pistons to allow for continuous operation of the manufacturing process. This ability to replace defective parts with parts from the buffer stock reduces the incentive to investigate the source of quality problems. In combination with the narrowly defined procedures of individual workers, the practice of maintaining buffer stocks disguises the interdependencies of the production process and prevents workers from seeing how their actions affect the system as a whole.

Fordist manufacturing was very successful at lowering the costs per vehicle; accordingly, between 1909 and 1916, the price of a Ford Model T fell by 60%. By the early 1920s this form of mass production allowed Henry Ford to make 2 million identical Model Ts every year at a very attractive price. By the mid-1950s, the Fordist manufacturing system dominated most of the world’s manufacturing industries.

Lean manufacturing

In the early 1950s, Toyota discovered that a smaller number of workers, each capable of doing multiple tasks, could turn out cars using less inventory, less investment, and committing fewer mistakes. Accordingly, under lean or just-in-time manufacturing, tasks are performed by teams in which each member can do any of the team’s tasks, including maintenance, inspection, and machine setup. Lean manufacturing encourages worker participation and discourages managerial authoritarianism—a key difference from Fordist manufacturing.

In designing the production process, lean manufacturing gives top priority to quality control. In contrast to the Fordist approach, it regards large inventory stocks as a source of costs and problems rather than a solution to them. With lower in-process inventories, quality problems of a particular assembly operation become visible faster. Thus, tool and equipment maintenance become more important. In addition, the idea of continuous improvement of operations is central to the lean manufacturing philosophy; most of these improvements are the result of suggestions from the factory floor. Under lean manufacturing, the worker who installs wheels and tires also maintains the equipment, cleans up the work area upon completion of other duties, and performs quality control functions. If the worker spots a flaw in the production process, he or she alerts the group leader. The manufacturing error is then corrected instantly, either while the car is still moving on the assembly line or after the line has been stopped by the group leader. Of course, shutting down the assembly line to correct defects requires highly skilled line workers who must be able to recognize and correct defects in order to restart the assembly line quickly.

In addition to increasing quality, lean manufacturing systems are able to turn out small batches of customized products on relatively short notice and at low cost. That makes it necessary to provide flexibility and quick setup capability in a factory, e.g., by reducing the time needed to change dies. As a result, lean manufacturing requires a different process flow design and layout within a plant, usually occupying much less floor space. For example, Jacobs Vehicle Equipment Co., a heavy-duty engine brake manufacturer in Bloomfield, Conn., reduced its floor space devoted to manufacturing from 240,000 to 120,000 square feet as a result of the introduction of lean manufacturing techniques.1

Lean inventories plus the ability to flexibly adapt to changes in demand place great strains on the flow of materials. In response, Toyota pioneered the use of the “kanban” method for moving parts and materials across the factory. Each of the containers transporting parts downstream in the production process carries a card. As the parts are used up, the card is sent back to the previous production operation where it signals the need to produce more of these parts. By maintaining a continuous, tightly controlled but decentralized flow of parts and materials in the factory, lean manufacturing allows flexible adaption of the production line to changes in the demand for the final product.

Manufacturing “cells” increase the flexibility of the lean manufacturing system. A cell is a cluster of clever machines and robots that is able to take instructions directly from a computer-aided design terminal. In a truly flexible factory, it would be possible not only to build different versions of the same car, like a coupe or a station wagon, on the same production line, but also to build completely different cars. For example, at two of its assembly plants Nissan installed a reconfigurable body assembly jig capable of building several different vehicles by simply reprogramming its software.2 At its engine plant in Anna, Ohio, Honda builds both automobile and motorcycle engines on the same line. However, investments in advanced technology do not always pay off. Toyota scaled back ambitious plans to automate final assembly in a plant scheduled to open in Japan in early 1993 because the resulting improvements in quality turned out to be too costly.3

With reduced inventories, the timely supply of materials from outside suppliers becomes crucial to the success of lean manufacturing. It is therefore no surprise to find relationships between car assemblers and suppliers to be characterized by communication and mutual commitment. These close relationships may help to explain the fact that lean manufacturing assemblers have chosen to buy directly from only a small number of “first-tier” suppliers. For example, Chrysler deals with 230 parts and materials suppliers in producing its new LH-platform.4 Its assembly is based on the lean manufacturing system. That compares to 456 suppliers for the 1992 version of the Chrysler New Yorker, a car introduced in 1988 and built according to the Fordist system.5

Ultimately, suppliers must also adopt lean manufacturing techniques in order to be able to meet the demands of the auto manufacturers. In addition, rather than produce parts according to predetermined specifications, outside suppliers must increasingly conduct product research and development both on their own and in consultation with assemblers.

Lean manufacturing comes to North America

Expanding the geographic boundaries of lean technology has also become a hallmark of Japanese auto companies as the so-called transplants have been remarkably successful in North America and Europe. In 1982, Honda of America began to assemble automobiles in Marysville, Ohio. Less than 10 years later, during 1991, seven Japanese transplants produced almost 1.4 million cars in the U.S. (see figure 1). Honda can now produce cars in North America as efficiently as those made in Japan, and Nissan’s Sunderland plant in England is referred to as one of the most efficient car plants in Europe.6 From figure 1 one can see that most transplant assembly firms have chosen locations in nonmetropolitan areas in the Midwest. Furthermore, joint venture arrangements between U.S. and Japanese companies were used to facilitate the transfer of technology.

1. U.S. transportation motor vehicle assembly plants

| Company | Plant location | Launch date | 1991 capacity | 1991 production |

|---|---|---|---|---|

| (in thousands) | ||||

| Honda | Marysville, OH | 1982 | 360 | 451* |

| East Liberty, OH | 1989 | 150 | ||

| Nissan | Smyrna, TN | 1983 | 250 | 134 |

| GM-Toyota (NUMMI) | Fremont, CA | 1984 | 240 | 207 |

| Mazda | Flat Rock, MI | 1987 | 240 | 165 |

| Toyota | Georgetown, KY | 1988 | 218 | 188 |

| Chrysler-Mitsubishi (Diamond-Star) | Normal, IL | 1988 | 240 | 154 |

| Isuzu-Fuji (Subaru-Isuzu Automotive) | Lafyatte, IN | 1989 | 120 | 58 |

| Ford-Nissan | Avon Lake, OH | 1992 | 135 in '93 | N.A. |

| Total | 1,818 | 1,357 | ||

*Total for Marysville and East Liberty.

Source: Ward’s Automotive Yearbook, 1990 and 1992. Capacity measured as straight time assembly

capacity; Nissan, Ford-Nissan, and Subaru-Isuzu capacity includes cars, trucks, and vans; all other capacity

in cars.

While technological changes were pioneered and successfully transplanted by Japanese producers, European and American auto manufacturers have been adopting the new manufacturing techniques in order to effectively compete internationally. For example, Ford has improved its assembly productivity by 36% since 1980. Some Ford plants have all but erased the labor cost advantage enjoyed by the most efficient Japanese auto producers; among these is Chicago’s Taurus plant.7 Similarly, Chrysler has made strong gains in manufacturing productivity during the past three years. Its adoption of lean manufacturing principles becomes visible as well in the development of the LH-cars, introduced in the fall of 1992. The LH-car was developed in 39 months with a technical staff of 740, as compared to the development of the K-car, which was introduced in the early 1980s and took 54 months and a technical staff of 2,000.8 GM improved its assembly productivity by 11% since 1980; one of the most prominent adjustments has been the launch of Saturn in 1991.

Implications for the Midwest

If they are to compete globally, the remainder of the region’s manufacturing industries must follow Midwest automakers and parts suppliers in adopting the more efficient lean manufacturing standards. A host of particular policy issues is crucial for the Midwest in sustaining the successful changeover to lean production in autos, and in broadening it to other manufacturing sectors. International competition and direct foreign investment in the U.S. were important elements supporting the introduction of lean manufacturing techniques into North America. The success of the Japanese transplants has demonstrated that manufacturing technology can be transferred internationally. Fostering openness to trade and investment are therefore crucial for the Midwest’s and nation’s success in an environment where advances in manufacturing technology are being made around the world. Within individual states, efforts have been made to support the adaptation of lean manufacturing technologies. For example, Pennsylvania instituted a “Manufacturing Innovation Networks” program that supports the growth of lean manufacturing networks by means of nine industrial resource centers. Other programs, like Michigan’s Technology Centers or Ohio’s Edison Technology Centers, are more broadly targeted and serve as an intermediary organization for technology development in specific industries.

Successful implementation of lean manufacturing in factories also rests on the ability to enhance skills and responsibilities of assembly line workers within a team-oriented management approach. This will require job training programs that teach how to improve quality and cooperative management in order to successfully harness ideas for improving the production process.

Last, but not least, lean inventories render frequent timely deliveries of parts and materials crucially important for the successful application of lean manufacturing. That places great emphasis on a well-designed and maintained system of public transportation infrastructure.

Tracking Midwest manufacturing activity

Manufacturing output index (1987=100)

| December | Month ago | Year ago | |

|---|---|---|---|

| MMI | 113.5 | 112.7 | 107.9 |

| IP | 111.7 | 111.1 | 108.1 |

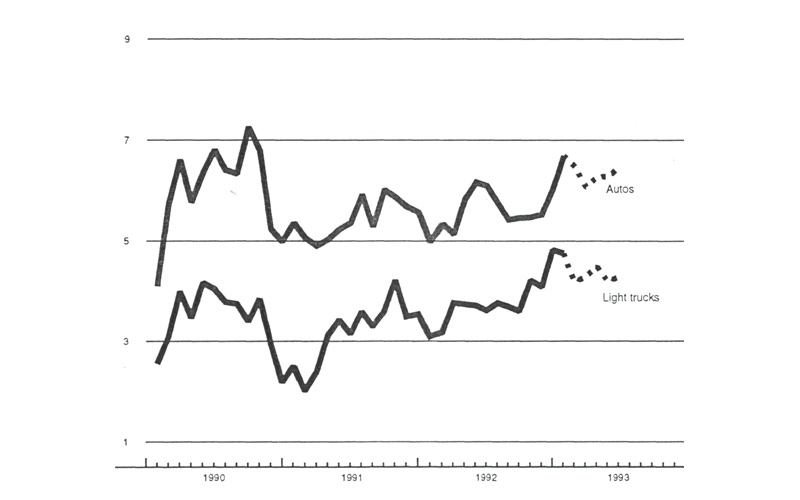

Motor vehicle production (millions, saar)

| January | Month ago | Year ago | |

|---|---|---|---|

| Autos | 6.7 | 6.1 | 5.0 |

| Light trucks | 4.8 | 4.8 | 3.1 |

Purchasing manager’s association: production index

| January | Month ago | Year ago | |

|---|---|---|---|

| MW | 67.4 | 66.3 | 46.8 |

| U.S. | 64.6 | 59.4 | 50.5 |

Motor vehicle production, millions (saar)

Note: Dotted lines are estimated production.

Sources: The Midwest Manufacturing Index (MMI) is a composite index of 17 industries based on month hours

worked and kilowatt hours. IP represents the FRBB industrial production index for the U.S. manufacturing

sector. Autos and light trucks are measured in annualized physical units, using seasonal adjustments

developed by the Federal Reserve Board. The PMA index for the U.S. is the production components of the NPMA

survey and for the Midwest is a weighted average of the production components of the Chicago, Detroit, and

Milwaukee PMA survey, with assistance from Bishop Associates and Comerica.

Auto production has been the center of improvements in manufacturing both for the Midwest and the nation in recent months and is likely to continue to drive manufacturing activity in the months ahead. The Board‘s manufacturing index for December increased 0.5% , but only 0.1% excluding autos and trucks.

The most recent production plans announced by the domestic auto industry call for a steady increase in car assemblies in the first and second quarters of l993, rising from an average annualized rate of 5.7 million units in the fourth quarter of 1992 to 6.4 million units in the first and second quarters of 1993. While these plans depend on an accompanying improvement in sales to be sustained, they provide a solid basis for expecting continued improvement in the Midwest’s manufacturing sector.

Notes

1 Industry Week, September 18, 1989, p. 26.

2 Jack Keebler, “Quick change artist,” Automotive News, November 23, 1992, p. 16i.

3 Mary Ann Mastery, “Stepping back,” Automotive News, October 26, 1992, p. 14i.

4 Platform refers to the structural underbody of a car. For example, the Dodge Intrepid, Chrysler Concorde, and Eagle Vision are separate models, yet are all LH-platform vehicles.

5 Ward‘s Automotive Yearbook, 1992, p. 53.

6 The Economist, “Survey: the car industry,” October 17, 1992, p. 6.

7 Joseph B. White, “GM’s labor cost disadvantage to Ford is placed at $4 billion a year by study,” Wall Street Journal, October 6, 1992, p. A2.

8 Bradley A. Stenz, “Importing solutions,” Wall Street Journal, October 1, 1992, p. Al.