Making Value for America: A study by the National Academy of Engineering

Production technology and the nature of work are changing rapidly, giving rise to job declines in the manufacturing sector. In this context, can the U.S. design policies that support manufacturing while providing greater opportunity for U.S. workers? This was the question asked of a study panel at the National Academy of Engineering, which produced “Making Value for America: Embracing the Future of Manufacturing, Technology and Work.”

On May 4, Nick Donofrio, who chaired the study committee, joined a panel of experts at the Federal Reserve Bank of Chicago to present the findings and implications from the report. Donofrio was the Executive Vice President for Technology at IBM and a member of the National Academy. Joining him were panelists Dan Swinney (Manufacturing Renaissance and study committee member), Chad Syverson (University of Chicago Booth School of Business and study commission member), Haven Allen (World Business Chicago) and Craig Freedman (Freedman Seating).

Setting the stage for the program was Bill Testa, Vice President and Director of Regional Programs at the Chicago Fed. Testa focused on the key role of manufacturing in the Midwest economy. Within the Midwest region, the manufacturing job base remains 53% more concentrated than in the U.S. as a whole. However, dramatic declines in manufacturing jobs have led many policymakers to pursue other economic development targets. Since 1969, when manufacturing accounted for roughly 40% of the regional job base, manufacturing employment has fallen to 13.5%. Testa noted that from 2000 through the recession of 2009, manufacturing jobs in the Seventh District states of Illinois, Indiana, Michigan, Wisconsin, and Iowa dropped by 35% or 1.16 million; and only 224,000 or 21% of those jobs have returned during the recovery to date.

Testa commented that some of this trend can be traced to technology and productivity. What took 1,000 workers to make in 1950 can be done by 200 today. Moreover, increasingly workers in manufacturing jobs are upskilling and are required to have the ability to work with advanced technology—and to do so at pay scales set by global competition. Despite the many challenges, Testa argued that the Midwest still holds some advantages for manufacturers, such as a strong supply chain and the infrastructure to move goods efficiently. Recreating the region’s network of rail, road, air hubs, and ports would be difficult elsewhere. Second, manufacturing directly comprises 20% of the region’s overall output, but more importantly is responsible for almost two-thirds of the research and development in the region. Additionally, the region’s universities are well positioned to create innovation in engineering and technical fields that can lead to new products and processes.

Donofrio presented the findings from Making Value for America. Donofrio emphasized that this was not a typical manufacturing study. He suggested that in some ways manufacturing is a 20th century word and that what matters today is not simply making things but adding value through production. Understanding where value is added is critical; and in many cases, value comes from services related to the final product. Specifically, he defined adding value as the process of using ingenuity to convert resources into a service or process that contributes additional value to a person or a society. In particular, the study was interested in how the nature of work is changing. Donofrio quoted former MIT president Charles Vest who said, “Far too much of our nation is waiting for new ways of work to arrive. We hear lots of rhetoric about how the nature of work will change, as it relates to some unknown distant future. The fact is that it is happening now, and we need a broader recognition of this fact and policies and education that reflects it.”

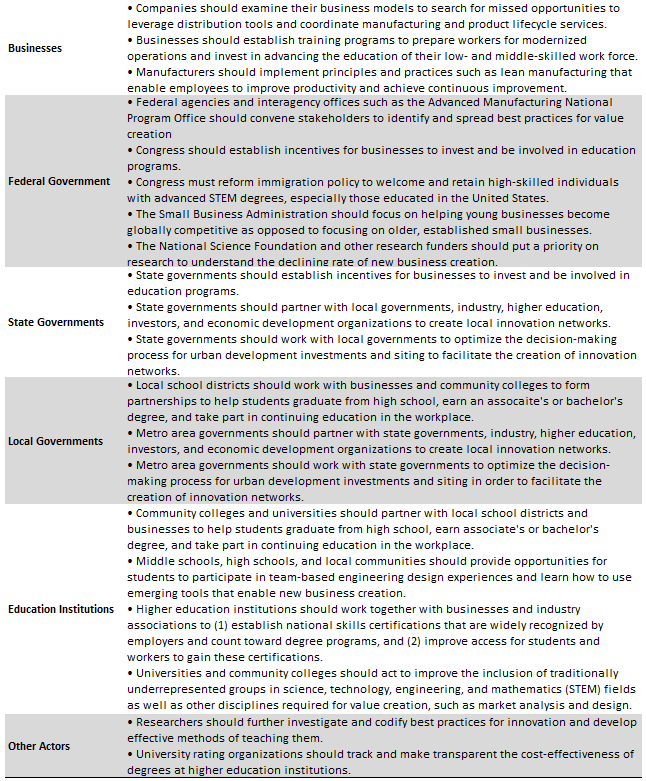

Donofrio noted that U.S. employment in manufacturing will never regain its historical levels, but growth will be facilitated by policy that focuses on adding value and innovation. Recommendations from the study focused on three areas—education, collaboration, and being inclusive. A goal is to develop a robust innovation ecosystem that includes business; federal, state, and local governments; economic development organizations; educational institutions; and research organizations. A partial list of recommendations appears in Table 1; the complete list is available online.

Table 1. Recommendations organized by actor

Chad Syverson kicked off the panel discussion by talking about the university’s role in supporting education at the pre K to 12th grade level. He noted that the University of Chicago has been active in urban education, ranging from the creation of charter schools to the creation of the Urban Education Lab. All of these efforts use rigorous social science evaluation to develop best practices for education.

Additionally, the university works directly to support entrepreneurship through the Polsky Center, which serves as a resource for supporting business formation. Syverson noted that the U.S. has had a 30-year downward trend in new business formation and that the dynamics behind this are not well understood. However, it is though business formation that significant innovation occurs, so the trend is disturbing, he said. Complementary services are provided by the Booth School of Business working with the Chicago Innovation Exchange, the 1871 tech incubator, and directly with businesses to disseminate best practices. Syverson noted that large amounts of value are left on the table when firms fail to keep up with best practices and that significant gains for the U.S. economy can be provided by better educating firms.

Haven Allen described the multitude of programs that can be found in Chicago that create manufacturing networks. These include national efforts such as the Digital Manufacturing and Design Innovation Institute (DMDII) and its related Illinois Manufacturing Labs. A clear goal is to connect local firms to this national network of innovative firms. This requires broad partnerships that include businesses, local community groups, and education. Allen stressed that training is key and that recent apprenticeship programs offered by organizations such as the Jane Addams Resource Center, the University of Illinois-Chicago, and Daley College provide models for supporting work force development. Finally, Allen emphasized that successful partnerships will focus on improvements in people, process, and product.

Craig Freedman offered the perspective of a manufacturer. Freedman suggested that the pace of change means that businesses and their workers need to get smarter at all levels. Business needs to link with education in order to make sure that relevant skills are learned at all grade levels. For example, Freedman cited the Manufacturing Connect program at Austin Polytech as a model that deserves replication. The school is located in the Austin community on the west side of Chicago. The program teaches high school students metal-working skills and provides them with certified credentials upon graduation. Local businesses partner with the school and provide apprenticeships and job shadowing opportunities.

Freedman also praised local training organizations such as the Jane Addams Resource Center, Daley College, and the 1000 Jobs Campaign as helping support critical work force development. Finally, Freedman suggested that more work needs to be done to promote the image of manufacturing as a good career path. Current perceptions of manufacturing are based on outdated notions of the industry that need correcting if young people will be attracted to these jobs.

Concluding the discussion was Dan Swinney. He noted that social inclusion should be a goal of the new emphasis of manufacturing rebirth in cities. He also cited the efforts of the Manufacturing Renaissance and the Manufacturing Connect program in the Austin Community in Chicago. Swinney stressed the importance of bringing these types of programs to areas that have suffered disinvestment. The challenges communities like Austin face are clear in the data. While unemployment in Chicago has fallen to 6.4%, in Austin it hovers near 30%. Similarly, manufacturing job loss in Austin is near 90%. However, to address the challenges faced by communities like Austin, Swinney argued, programs like Manufacturing Connect must be scaled up, since they currently only reach a small subset of students.