The following publication has been lightly reedited for spelling, grammar, and style to provide better searchability and an improved reading experience. No substantive changes impacting the data, analysis, or conclusions have been made. A PDF of the originally published version is available here.

Economic development policymakers are energetically devising strategies to return idle or abandoned industrial sites—so-called brownfields—to productive use. The most ardent proponents expect the benefits to be twofold. First, they believe brownfield redevelopment can help attract jobs back to the central cities, where unemployment runs high and where some popular notions of justice suggest that the wealth-generating activities of the past should not be a costly legacy to the nation’s urban poor. Second, many argue that urban-oriented brownfield redevelopment policies are needed to offset the current biases toward greenfield development that tend to produce urban sprawl. Pristine greenfields are often cheaper to develop, but the regionwide effects of such development may be less beneficial as congestion, environmental degradation, and other growth-related problems can accompany spurts of development on the urban fringe.1

While the potential benefits of brownfield redevelopment are substantial, unfortunately so are the barriers. These sites are popularly referred to as brownfields because they often are contaminated with pollutants and environmental hazards that require extensive remediation before new construction or redevelopment is possible. The challenges to redeveloping urban brownfields extend well beyond the difficulties of cleaning them up. Urban development that aims to restore bustling factories employing semi-skilled workers at high wages may be particularly hard to achieve given changes in transportation practices and modes of production. In many cases, because of the changing industrial base of cities, nonindustrial development is more likely on brownfield locations, but such development often requires more stringent and therefore more costly cleanup. Successful brownfield redevelopment strategies will require creativity and must address both economic and environmental constraints.

The environmental issue and CERCLA

The backdrop to brownfield redevelopment is the Comprehensive Environmental Response, Compensation, and Liability Act of 1980 (CERCLA).2 This federal legislation established the Superfund Program for identifying and cleaning up contaminated sites throughout the U.S. Superfund has been criticized because it potentially assigns responsibility for site cleanup to current or prospective property owners (and perhaps lenders), even if they never contributed to the contamination. This responsibility can have the effect of freezing redevelopment rather than accelerating it. Current owners may choose to fence in or disguise currently contaminated sites rather than expose their liability to cleanup during the sales transaction process. At the same time, prospective buyers may be reluctant to purchase sites with uncertain but potentially steep cleanup costs. The U.S. Environmental Protection Agency estimates that a survey of an industrial site can cost from $1,000 to $10,000; drilling and testing soil core samples can cost as much as $70,000.3 These efforts only establish the extent of the environmental problem; if a cleanup is required, costs can rapidly escalate.

Several states have enacted measures to address the “who pays?” problem of CERCLA. One of the most popular has been to issue a liability release to the owner of a brownfield site once the site has been cleaned up and certified for redevelopment. Minnesota has been a leader in this area, providing financial assistance to the prospective purchaser to conduct assessments of the site’s condition.4 The prospective purchaser then submits a cleanup plan to the state. Once it is approved, the purchaser undertakes the cleanup and is thereupon released from further liability. While this plan frees the owner from state liability, federal liability stays in effect. If similar cleanup standards and release from liability could be extended to federal rules and regulations, then these state programs would become even more effective. It has also been suggested that similar certification processes be available to lenders so that the latter do not fear uncapped liabilities when they make loans for site cleanups. Since the lack of available financing is often seen as a primary hurdle in redevelopment, reducing the risk and uncertainty of lenders would help ease this problem.

A second problem with existing federal rules is the requirement that brownfields be returned to nearly pristine condition. This can lead to an excessively costly cleanup undertaken without regard to the future use of the site. The inefficiencies in cleaning up a site beyond what is necessary to protect health and welfare are obvious. Greater efficiency would enable using funds and resources for some other worthwhile private or public use instead, or for accelerating the cleanup of other contaminated sites.

Policies to certify sites as meeting standards for particular levels of cleanliness would seem to be a natural vehicle to promote redevelopment. States have begun to implement such policies, such as the aforementioned program in Minnesota. If the property needs to be only partially cleaned up in order to be appropriate for its new purpose, a deed restriction is attached and remains in effect for any future sale. While the property remains subject to judicial and regulatory actions under federal laws, such state programs commonly include a pledge by the state to stand by the property owners in the event of federal action.

Another way in which government can help with brownfield redevelopment is by improving the technology transfer of best practices for handling cleanups. Few developers know the pros and cons of different cleanup techniques; improving the information available on the subject can reduce costs and increase certainty about the methods chosen.

Finally, some form of public financing may be needed to make brownfields attractive for investment. Even with greater clarity in cleanup regulations and more certainty about owner and lender liability, the additional site preparation costs associated with brownfields can chase development to greenfield locations. Public financing options range from cleaning the site at public expense to providing grants, loans, or loan guarantees to support cleanup efforts. Government support for commercial site development is not unusual; local and state governments have long been willing to spend public funds to construct roads and sewers needed for greenfield development. Brownfield sites often do not need such infrastructure expenditures. If government instead contributed to the funding of cleanup, this could help make redevelopment more feasible.

Identifying the most attainable forms of urban development

State programs to certify site cleanup to minimum levels, such as for industrial uses, would seem to fit hand-in-glove with the desires of urban policymakers to revive manufacturing activity in central cities. However, these desires may be largely wishful thinking. During the early part of this century, many cities were thriving centers of manufacturing growth. Historically, cities in the Midwest were noted for their high concentration in manufacturing activities. American cities that developed during the industrial age (1830-1945) had on average 11% of their total land devoted to industrial use.5 For many industries in the Midwest, bringing together a large volume of bulky raw materials such as coal, iron ore, limestone, or livestock required a central terminal where rail, barge, and freighter traffic could converge. At the same time, mass production of autos, steel, food processing, and machinery required large numbers of workers. In the pre-auto age, workers could reach the factory only if they lived within walking distance or streetcar distance.

Today, many of the methods, needs, and physical requirements of manufacturing have changed. As truck transport supplanted rail, narrow city streets and high population density made the movement of goods in and out of urban factories difficult. Suburban locations with good highway access became preferred. Older industrial plants were built in multistory configurations, while new plants require more floor space and tend to be built in one story. Because manufacturers are now often averse to locating in urban areas irrespective of environmental problems, cleaning up contaminated sites may not be enough, in many instances, to guarantee bringing back industrial jobs to central cities.

Such historic changes are evident in the long-term decline in manufacturing employment in midwestern cities, a decline that began before the concern about environmental impediments (see figure 1). As others have noted with some irony, manufacturers who left the central city during pre-CERCLA decades were quick to cite lack of available space as a prominent reason for seeking greener pastures. In many central cities today, lack of space to expand does not seem to be the major issue, For example, a recent survey of property in Chicago found that an estimated 18% of all land in industrial areas, or 1,500 acres, is either inactive or vacant.6

1. Manufacturing employment

| 1954 | 1972 | 1990 | |

| (thousands) | |||

| Chicago | 615.7 | 430.1 | 225.7 |

| Indianapolis | 75.9 | 92.8 | 58.4 |

| Detroit | 296.5 | 180.4 | 68.8 |

| Milwaukee | 123.9 | 106.3 | 60.9 |

Service options

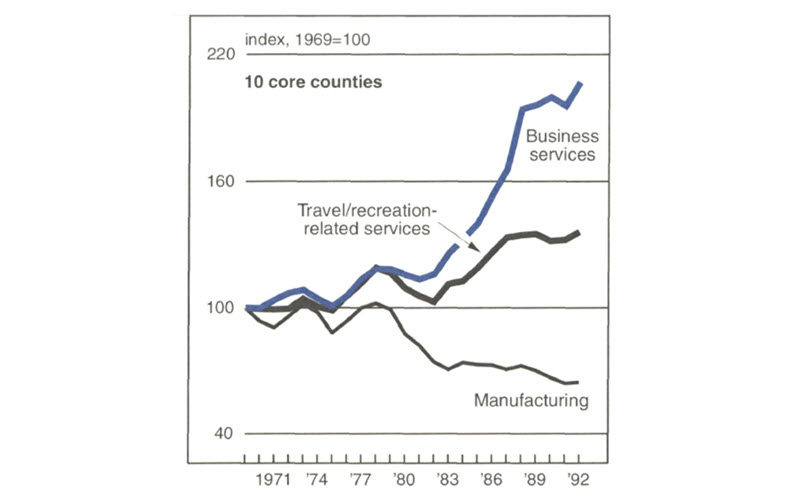

Part of successfully redeveloping brownfields may mean seeking alternative forms of development quite different from the original function of the site. This is particularly the case because central-city economic growth today increasingly derives from service industries.7 In contrast to the difficult prospects in the manufacturing sector, core counties (those containing the boundaries of a major city) have managed to capture part of several high-growth industries. Take business services, for instance—services sold to other businesses such as accounting, legal, or finance. Income in this sector has grown by over 206% in ten midwestern core counties from 1969 to 1992. Similarly, the travel/tourism/recreational industry has also grown rapidly in core counties (see figure 2). Successful central-city redevelopment may thus require converting former industrial sites to commercial, service, or even residential uses.

2. Personal income by source

Sources: U.S. Department of Commerce, Bureau of Economic Analysis, Regional Economic Information Systems.

Many service jobs and related spin-off jobs, such as those in hotels, food service, or janitorial services, are accessible to urban residents but pay low wages. Higher-paying service jobs require higher skill levels that budget-pinched inner-city schools are unable to provide to their graduates. While many business services may prefer urban locations, the urban workforce may not be able to qualify for the higher-paying jobs that those firms create. Moreover, manufacturing is no longer an easy stepping-stone to middle-class income for less-skilled workers, as it once was. So-called lean manufacturing technology has become the order of the day among manufacturers who must now keep abreast of global competition.8 The more complex and more numerous tasks involved with these new technologies require better education and higher skill levels.

Location studies suggest that the availability of a skilled labor force is a critical factor for both manufacturing and service industries. If the full redevelopment potential of urban sites is to be realized, the quality of the city labor pool must be enhanced, or service firms may follow the lead of manufacturers and move to greenfield sites near where their workforce increasingly lives. Clearly, policies designed to improve the quality of urban schools and to upgrade the skill of the urban workforce will be important to improving the development potential of urban land.

Conclusion

Addressing the shifting urban economic base means that brownfield sites need to be closely inventoried so that their appropriateness for different types of redevelopment projects can be established. Identifying those sites that may require the least amount of cleanup and re-engineering while delivering the greatest economic development impact is a sound strategy and can ensure that resources are not squandered cleaning up a location that would be of little redevelopment value even when returned to sound environmental condition.

However, while making such a ranking is an appropriate first step, it may not lower remediation costs as much as hoped. Allowing differential levels of site cleanup will lower costs only if small-cleanup uses of land will actually be undertaken. Unfortunately, today’s urban growth patterns favor converting parcels from industrial to commercial or residential uses, so actual cleanup standards will often remain quite high.

Finally, a critical aspect of addressing brownfield redevelopment is to assemble the proper mix of programs and incentives to fit the specific site and the specific needs of the redevelopment project. No single approach can ensure that a brownfield will be an attractive location for redevelopment.

Brownfields can be successfully redeveloped if public policies are designed to address both their economic and environmental challenges. Reducing the risk and uncertainty associated with redeveloping these sites, and looking at possible alternative development paths, will help bring brownfields back into productive use.

Tracking Midwest manufacturing activity

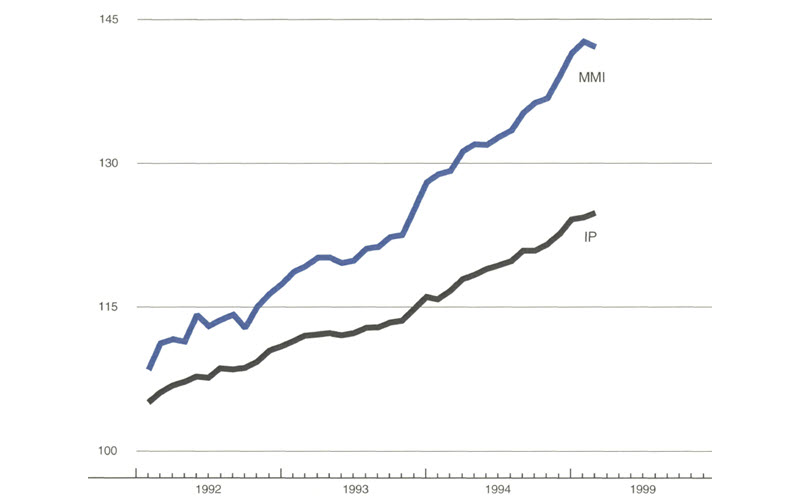

Manufacturing output indexes (1987=100)

| February | Month ago | Year ago | |

| MMI | 142.1 | 142.7 | 129.2 |

| IP | 124.8 | 124.3 | 116.7 |

Motor vehicle production (millions, seasonally adj. annual rate)

| February | Month ago | Year ago | |

| Autos | 7.2 | 7.2 | 7.2 |

| Light trucks | 5.2 | 5.5 | 5.3 |

Purchasing managers’ surveys: net % reporting production growth

| March | Month ago | Year ago | |

| MW | 57.9 | 67.3 | 72.2 |

| U.S. | 53.6 | 54.8 | 58.7 |

Manufacturing output indexes, 1987=100

Sources: The Midwest Manufacturing Index (MMI) is a composite index of 15 industries based on monthly hours worked and kilowatt hours. IP represents the Federal Reserve Board industrial production index for the U.S. manufacturing sector. Autos and light trucks are measured in annualized units, using seasonal adjustments developed by the Board. The purchasing managers’ survey data for the Midwest are weighted averages of the seasonally adjusted production components from the Chicago, Detroit, and Milwaukee Purchasing Managers’ Association surveys, with assistance from Bishop Associates, Comerica, and the University of Wisconsin-Milwaukee.

Midwest manufacturing output growth eased in recent months. Industrial output in the region slipped in February, according to the Midwest Manufacturing Index, after surging in the three months ended in January. Light vehicle production also flattened out on a seasonally adjusted basis, and assembly schedules imply a small decline in output in the second quarter. Purchasing managers’ surveys around the region pointed to further deceleration in industrial output growth in March, but growth remained positive, and at a moderate pace.

Notes

1 For an excellent overview of the brownfield issue, see Charles Bartsch and Elizabeth Collaton, “Industrial site reuse, contamination, and urban redevelopment: Coping with the challenges of brownfields,” Northeast-Midwest Institute, Washington, DC, December 1994.

2 42 U.S. Code 9607 (A).

3 Casey Burko, “The quagmire of industrial-site cleanups,” Chicago Enterprise, The Commercial Club of Chicago, September/October 1994, pp. 26-27.

4 Two examples of Minnesota’s legislation in this area are the Minnesota Environmental Response and Liability Act and the Minnesota Contaminated Site Cleanup and Development Account. For a more complete description of these and other state actions, see “Recycling industrial sites in Erie County,” report of the Environment and Development Seminar, State University of New York at Buffalo School of Law, May 1994.

5 J. Thomas Black, “Recycling inactive urban industrial sites,” Urban Land Institute on the Future: Urban Growth Development Prospects and Issues, Urban Land Institute, Washington, DC, 1994, p. 36.

6 Ibid., pp. 38-39.

7 Ibid., pp. 40-41.

8 Ibid., p. 43.